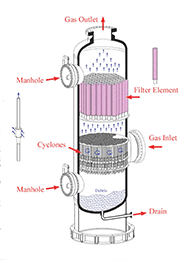

Scrubber

Vertical separators, are usually selected when the gas liquid ratio is high.

In a scrubber, the fluid enters the vessel through an inlet device whose primary objectives are to achieve efficient bulk separation of liquid from the gas and to improve flow distribution of both phases through the separator. Liquid removed by the inlet device is directed to the bottom of the vessel.

The gas moves upward, usually passing through a mist extractor to remove any small entrained liquid droplets, and the vapor phase flows out of the vessel. Liquid removed by the mist extractor is coalesced into larger droplets that then fall through the gas to the liquid reservoir in the bottom.

There are several types of centrifugal separators that serve to separate entrained liquids, and solids if present, from a gas stream. For mist extraction applications, reverse-flow, axial flow and recycling axial-flow cyclones are typically used in multi-cyclone bundles. Cyclonic mist extractors use centrifugal force to separate solids and liquid droplets from the gas phase based on density difference. Very high G forces are achieved which allows for efficient removal of small droplet sizes. The main advantage of cyclonic mist extractors is that they provide good removal efficiency at very high gas capacity. This generally allows for the smallest possible vessel diameter for a given gas flow. Cyclonic mist extractors are often used in low liquid load gas scrubbing applications, and for high pressure Gas-liquid separation.